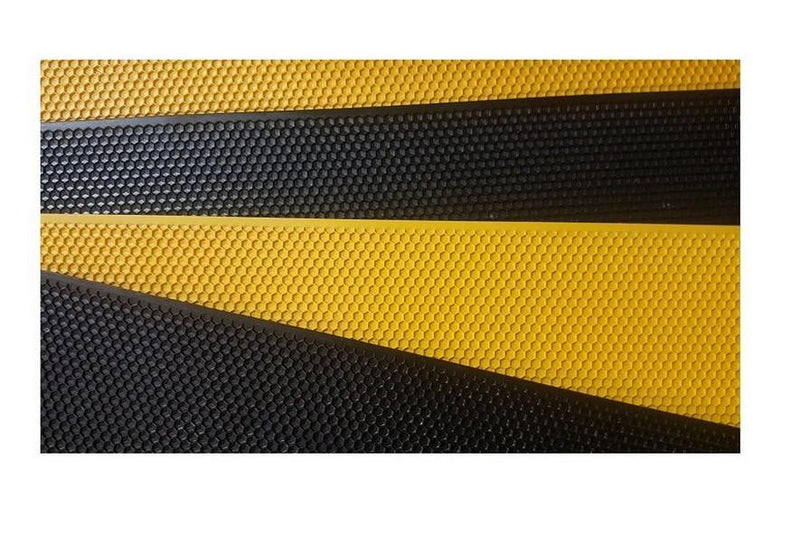

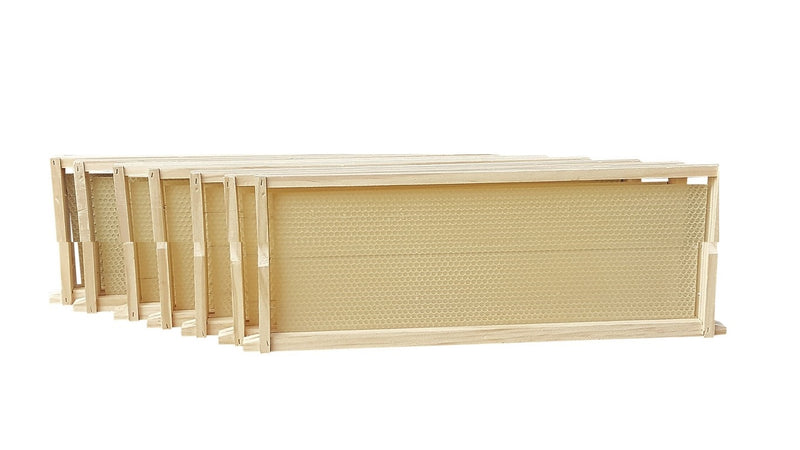

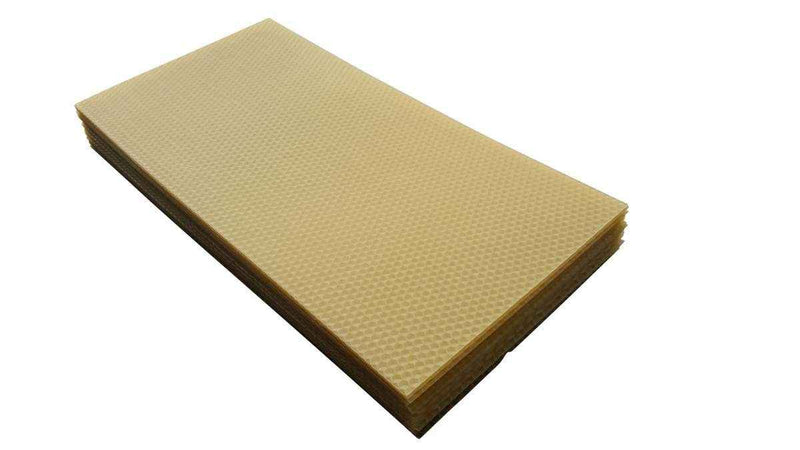

Our wax embossing roller is the perfect tool for beekeepers who want to recycle leftover beeswax into high-quality foundation sheets. This manual roller creates precise honeycomb patterns on plain beeswax sheets, providing your bees with an ideal base for comb building. Made for durability and ease of use, it’s a long-lasting machine that lets you produce unlimited wax foundations for your hives.

Beeswax foundation sheet machine

Instruction Manual

I. Before using the machine, lubricating oil should be applied to the four shaft sleeves and four gears.

Ⅱ. Description of each component:

1. The rack should be firmly fixed on the shelf during use.

2. The two m10 * 50mm screws on the cover are used to adjust the thickness of the Beeswax foundation sheet , with a tightening of about 50g per pack of Beeswax foundation sheet (30 pieces) for every sixth turn of the tube.

3. When in use, the cover fixing wire should be locked tightly.

4. Adjust the capping thread according to your own needs.

5. Oil eyes should be filled with oil every 20-30 packs of Beeswax foundation sheet.

6. The upper and lower rollers should avoid pressing hard objects or gravel.

7.8.9. When using variable speed gears, timing gears, and shaft heads, oil should also be injected.

10. The shaft sleeve should be checked regularly for wear.

11. Adjuster: Used to adjust the uniformity of the front and rear slopes of the Beeswax foundation sheet. The usage method is as follows:

(1) Rotate clockwise to make the nest base machine crush out the Beeswax foundation sheet;

(2) Gently remove the Beeswax foundation sheet, remember not to invert the top and bottom, front and back, and raise both hands towards the bright spot;

(3) Observe whether the left and right sides of the Beeswax foundation sheet are exposed on one side and exposed on the other. If the left side is exposed, loosen the screw A on the adjuster slightly, and tighten the corresponding screw B slightly. Otherwise, the opposite is true. The screws A and B should be tightly pressed against each other.

12. The stainless steel knife with automatic edge cuttings is finely crafted and should be protected from collision damage.

13. The compression spring should be placed in the center of the shaft sleeve.

Attachment: Daily Maintenance of Beeswax foundation sheet Machine

Regularly check whether the oil hole of the Beeswax foundation sheet machine is blocked by foreign objects. If it is blocked, disassemble and clean the oil hole.

Attention should be paid during installation

(1) Pay attention to the direction of the oil eye on the shaft sleeve.

(2) Be careful not to crush the drum with a stainless steel knife

(3) The markings on the timing gear should be aligned.

Please do not disassemble it yourself if you are not proficient.